Industrial machines, together with presses, employ the C Type – Helical Type mechanical configuration due to its essential requirements for precision strength together with durability. The machinery incorporates both a ‘C’-shaped framework with its helical gear operational system for delivering better torque capacities along with smooth operation abilities. The angled teeth arrangement in helical gearing produces both quiet operation and high efficiency by reducing shock loads as well as wear throughout its operational life.

Metal forming industries, along with stamping and punching operations and assembly tasks, depend on C Type – Helical Type press machines. Users can access the working area from three sides through the C-frame structure, which provides efficient integration capabilities for automated production and manual loading/unloading operations. Helical gear technology distributes power consistently so the machine operates quietly and achieves extended service life.

Businesses throughout automotive manufacturing, along with appliance production, electronics and general metalworking, prefer C Type – Helical Type machines because of their efficiency and reliability. These machines deliver superb operational control together with precision performance while requiring minimal upkeep, thus making them an intelligent purchase option for businesses focused on production speed enhancement and quality improvements.

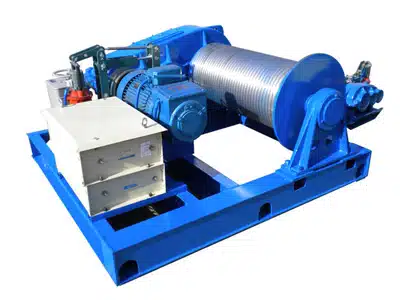

Industrial Winch Manufacturers

- IS 807: 1976 (For design Manufacturing & Testing)

- Capacity : 1 ton to 20 ton

- Lift 6 m to 60 m