Jib Crane Manufacturer in Ahmedabad

- Jib cranes are an economical solution for moving materials within an individual workstation, for transferring materials from work area to work area or for serving as auxiliary lifting devices under overhead cranes.

- Styles range from entirely self-supporting to styles that mount to existing building columns, resulting in low costs compared to some overhead lifting systems.

- Because they are self-supporting, free standing jib cranes are well suited for outdoor use and can be fully weatherized

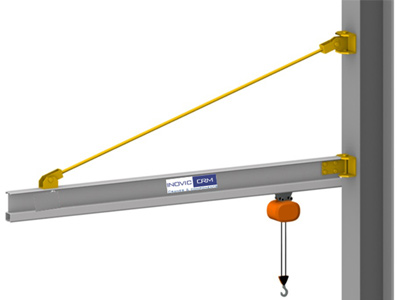

Aluminum Wall Bracket Jib Crane

- 180° degree rotation

- Utilizes a standard I-beam of Aluminum boom, a tie rod threaded at ends, a fabricated beam bracket, and two wall brackets; one for the tie rod and one for the boom.

- Allows maximum usage of the work area, including work close to the existing structure, because there are no supporting components under the boom.

- This design is the most economical style of jib crane, provided overhead clearance or building column strength is not a limiting factor.

- Hardware for mounting to wall or column supplied by others.

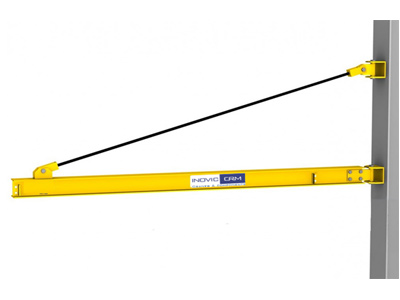

Wall Bracket Jib Crane

- 200° degree rotation

- Utilizes a standard I-beam boom, a tie rod threaded at both ends, a fabricated beam bracket, and two wall brackets; one for the tie rod and one for the boom.

- Allows maximum usage of the work area, including work close to the existing structure, because there are no supporting components under the boom.

- This design is the most economical style of jib crane, provided overhead clearance or building column strength is not a limiting factor.

- Hardware for mounting to wall or column supplied by others.

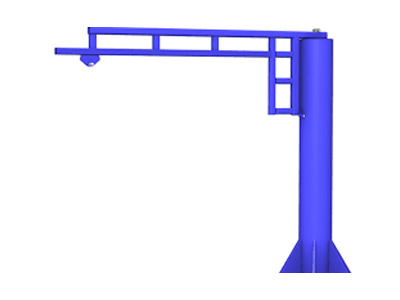

Free Standing Jib Crane

- 360° rotation.

- Allows for electrified, motor driven, powered rotation through various collector ring assemblies.

- The boom or I-beam is designed to meet all specifications utilizing a 25% factor of rated load for impact and 15% of rated load for hoist and trolley weight.

- The pipe mast or column is designed to give maximum strength and minimum deflection to resist bending, buckling, and crushing as well as wear by the turn-on roller assembly.

- workstation jib cranes are an ideal, lightweight ergonomic solution for smaller capacity loads up to 1,000 lbs., spans to 16 ft. Lightweight boom design makes the jib easier to rotate and position.

- The top bearing assembly utilizes a Timken tapered roller bearing provided with grease fitting for proper lubrication.

- Free standing jib cranes are available in three basic styles to suit specific applications:

- base plate mounted,

- foundation mounted

- sleeve insert mounted.

- 360° rotational capability can maximize the utilization of any work area. No additional support is needed other than the specified reinforced concrete foundation.

Work-Station Jib Crane

- Workstation Jib Cranes offer easy, ergonomic lifting and transfer of repetitive loads.

- These small, nimble cranes are faster than motorized jibs and are very affordable.

- Our workstation jibs can be permanently foundation-mounted, portable with counterweight bases, wall-mounted, or foundationless to best suit your needs: Workstation Jib Cranes offer easy, ergonomic lifting and transfer of repetitive loads.

- These small, nimble cranes are faster than motorized jibs and are very affordable.

- Our workstation jibs can be permanently foundation-mounted, portable with counterweight bases, wall-mounted, or foundationless to best suit your needs.

Mast Type Jib Crane

- INOVIC CRM India Pvt. Ltd. mast mounted jib cranes offer a lower cost alternative to free standing jib cranes.

- Full 360° rotation, without requiring a large mounting foundation (which can cost more than the crane).

- Requires top and bottom support of the mast to building floor and overhead building steel.

- Power rotation is available on all models.